Material:lāʻau lapaʻau titanium alloy

Hōʻike huahana

| 'ikamu helu. | Hōʻike | |

| 11.07.0115.004124 | 1.5*4mm | Non-anodized |

| 11.07.0115.005124 | 1.5*5mm | |

| 11.07.0115.006124 | 1.5*6mm | |

| 'ikamu helu. | Hōʻike | |

| 11.07.0115.004114 | 1.5*4mm | Anodized |

| 11.07.0115.005114 | 1.5*5mm | |

| 11.07.0115.006114 | 1.5*6mm | |

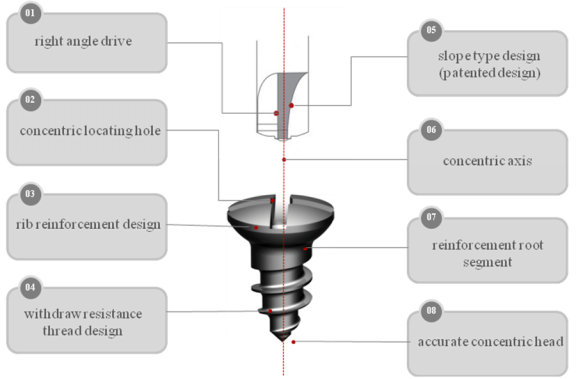

Nā hiʻohiʻona:

•lawe ʻia ka titanium alloy e hoʻokō i ka paʻakikī maikaʻi loa a me ka maʻalahi

•Kuikilana TONNROS CNC ʻoki ʻoki ʻoki ʻoki

•ʻO ke kaʻina hana oxidation kūʻokoʻa, hoʻomaikaʻi i ka paʻakikī o ka ʻili a me ka pale ʻana

Mea hana hoʻohālikelike:

kea poʻo wili hoʻokele: SW0.5 * 2.8 * 75mm

lima hoʻopili wikiwiki pololei

ʻO nā ʻaoʻao chamfered nā ʻaoʻao haʻahaʻa haʻahaʻa haʻahaʻa a me nā ʻaoʻao pā ākea ākea ʻaʻohe palpability. Loaʻa i ka lōʻihi i hoʻopilikino ʻia.

ʻO nā pōmaikaʻi o nā wili hao titanium:

1. Ka ikaika kiʻekiʻe. ʻO ka nui o ka titanium he 4.51g / cm³, ʻoi aku ka kiʻekiʻe ma mua o ka alumini a haʻahaʻa ma mua o ke kila, keleawe a me ka nickel, akā ʻoi aku ka kiʻekiʻe o ka ikaika ma mua o nā metala ʻē aʻe. ʻO ka wili i hana ʻia me ka titanium alloy he māmā a ikaika.

2. ʻO ke kūpaʻa ʻana o ka corrosion maikaʻi, ka titanium a me ka titanium alloy i nā media he nui paʻa loa, hiki ke hoʻopili ʻia nā wili o ka titanium alloy i nā ʻano ʻano maʻalahi corrosive.

3. ʻO ke kūpaʻa wela maikaʻi a me ka haʻahaʻa haʻahaʻa haʻahaʻa. Hiki i nā wili o Titanium alloy ke hana i nā mahana a hiki i 600 ° C a me 250 ° C, a hiki ke mālama i ko lākou ʻano me ka ʻole o ka loli.

4. Non-magnetic, non-toxic.Titanium mea he nonmagnetic metala aʻaʻole e magnetized i kiʻekiʻe loa magnetic fields.Not wale non-toxic, a me ka maikaʻi kūpono me ke kino kanaka.

5. Ka hana anti-damping ikaika. Hoʻohālikelike ʻia me ke kila a me ke keleawe, ʻo ka titanium ka lōʻihi o ka vibration attenuation manawa ma hope o ka haʻalulu mechanical a me ka vibration uila. Hiki ke hoʻohana ʻia kēia hana e like me ke kani kani, nā ʻāpana haʻalulu o nā mea wili ultrasonic lapaʻau a me nā kiʻi ʻoniʻoni o nā leo leo kiʻekiʻe.

Hoʻolālā milo no ka hoʻomaka ʻana o ka wili wikiwiki a me ka torque hoʻokomo haʻahaʻa. Nui nā koho o nā papa a me nā mesh, me nā mastoid a me nā kino kino, a me nā uhi puka burr no nā shunt.

ʻOi aku ka paʻa o ka wili, ʻoi aku ka maikaʻi?

Hoʻohana mau ʻia nā ʻūlū i ka ʻokiʻoki ʻana e hoʻopaʻa i ka wahi haʻihaʻi, hoʻopaʻa i ka pā i ka iwi, a hoʻopaʻa i ka iwi i ka pahu hoʻoponopono i loko a i waho paha.

Eia nō naʻe, i ka piʻi ʻana o ka ikaika, loaʻa i ka wili ka ikaika nui loa (Tmax), ma ia manawa e hoʻemi ʻia ka ikaika paʻa o ka iwi ma kahi mamao iki. Hoʻohana pinepine ia ma ke ʻano he ʻāpana e ana i ka ikaika paʻa o ka screw.I kēia manawa, ʻaʻole ʻike ʻia ka pilina ma waena o ka torque kiʻekiʻe a me ka ikaika huki.

ʻO ka maʻi maʻi, hoʻokomo pinepine nā kauka orthopedic i ka screw me kahi o 86% Tmax. Akā naʻe, Cleek et al. ʻike ʻia ʻo 70%Tmax i hoʻokomo ʻia i ka tibia o nā hipa hiki ke hoʻokō i ka POS kiʻekiʻe loa, e hōʻike ana e hiki ke hoʻohana ʻia ka ikaika torsion kiʻekiʻe ma ke kino, e hōʻemi ana i ka paʻa o ka hoʻoponopono.

ʻO kahi noiʻi hou o ka humerus i nā cadavers kanaka e Tankard et al. uaʻikeʻia ua loaʻa ka POS kiʻekiʻe loa ma 50% Tmax. ʻO nā kumu nui o nāʻokoʻa o nā hopena i luna nei paha ka likeʻole o nā mea hoʻohālike i hoʻohanaʻia a me nā kūlana ana likeʻole.

No laila, ʻo Kyle M. Rose et al. mai ʻAmelika Hui Pū ʻIa i ana i ka pilina ma waena o Tmax like ʻole a me POS e nā wili i hoʻokomo ʻia i loko o ka tibia o nā cadavers kanaka, a nānā pū i ka pilina ma waena o Tmax a me BMD a me ka iwi cortical iwi mānoanoa. Ua paʻi hou ʻia ka pepa ma Techniques in Orthopedics. The results show that the maximum and like POS hiki ke loaʻa ma 70% a me 90% Tmax me ka screw POSTmax o 90% nui aʻe me ka screw POSTmax o 90% nui aʻe ma mua o 90% Tmax me ka nui o ka screw POStorque, ʻo 100% Tmax. ʻAʻohe ʻokoʻa o ka BMD a me ka mānoanoa cortical ma waena o nā pūʻulu tibia, a ʻaʻohe pilina ma waena o Tmax a me nā mea ʻelua ma luna. ʻOiai hiki i ka 70% a me 90% Tmax ke hoʻokō i ka POS like, aia kekahi mau mea maikaʻi i ka hoʻopaʻa ʻana i ka wili, akā ʻaʻole pono ka torque ma mua o 90%, inā ʻaʻole e pili ka hopena fixation.

Source: The Relationship Between Insertional Torque and Pullout Strength of Surgical Screws. Techniques in Orthopedics: June 2016 - Volume 31 - Issue 2 - p 137–139.