Hot Selling for Eye Socket Plate - anatomical titanium mesh-3D cloud shape – Shuangyang Detail:

Material: medical pure titanium

Product specification

|

Item No. |

Specification |

|

12.09.0440.060080 |

60x80mm |

|

12.09.0440.080120 |

80x120mm |

|

12.09.0440.090090 |

90x90mm |

|

12.09.0440.100100 |

100x100mm |

|

12.09.0440.100120 |

100x120mm |

|

12.09.0440.120120 |

120x120mm |

|

12.09.0440.120150 |

120x150mm |

|

12.09.0440.150150 |

150x150mm |

|

12.09.0440.150180 |

150x180mm |

Features & Benefits:

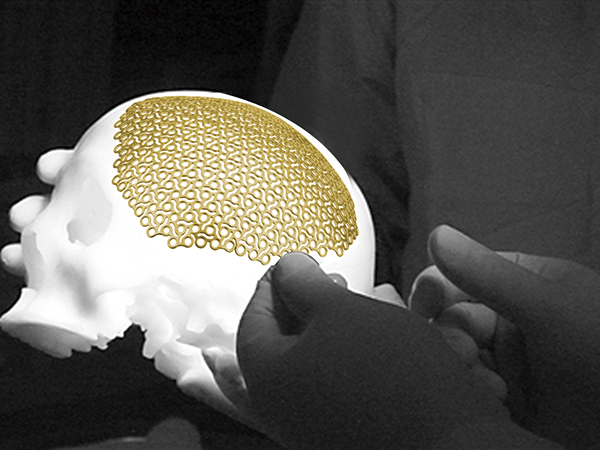

Digital Reconstruction of the Skull

CT thin layer scan the skull before operation, layer thickness should be 2.0m. Transmit the scan data into workstation, make 3D reconstruction. Calculate skull shape, simulate the defect and make model. Then make individual patch by titanium mesh according to the model. Undergo the surgical skull repair after getting patient’ s approval.

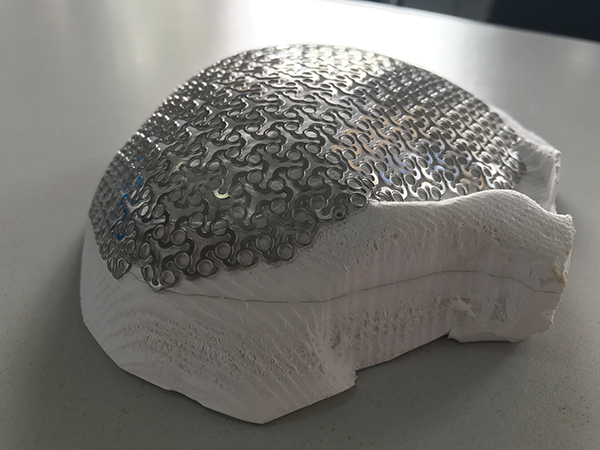

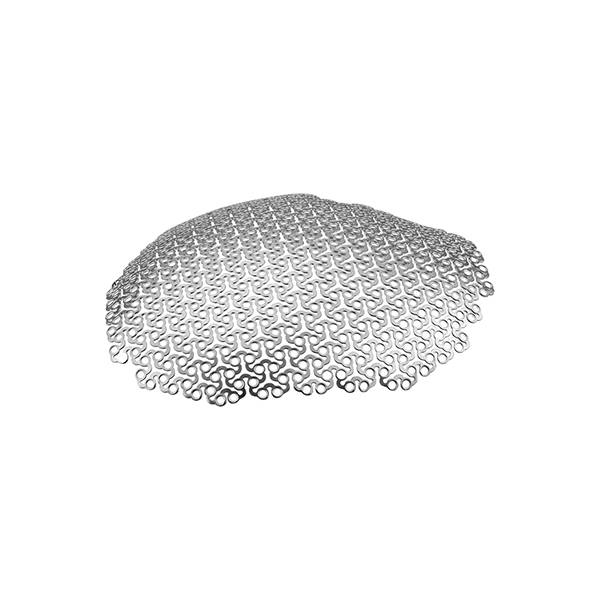

• 3D titanium mesh possesses moderate hardness, good extensibility, easy to model. Recommend preoperative or intraoperative modeling.

• 3D titanium mesh is more applicable to meet the region where has complex curved surface or big curve. Suitable for the restoration of various part of skull.

• shorten operation time, reduce the pain of patients, and reduce the risk of surgery and postoperative complications. The complications of skull repair are mainly infection, subcutaneous effusion, skin chronic ulcer and so on.These complications are considerably related to shaping precision of the repair materials. The sharp edges of titanium mesh can cause skin pain and even cut the skin, it is difficult for the single curvature of titanium mesh to fit the different parts of the skull.

Innovative design, domestic exclusive

• make personalize titanium mesh according to the patient’s CT scans before operation. No need more reconstruction or cut, mesh has smooth edge.

• unique oxidation processof surface hep the ttanium mesh get beter hardness and wer rsistance.

domestic exclusive enterprise who get the registration certificate for anatomical titanium mesh.

Matching screw:

φ1.5mm self-drilling screw

φ2.0mm self-drilling screw

Matching instrument:

cross head screw driver: SW0.5*2.8*75mm

straight quick coupling handle

cable cutter (mesh scissors)

mesh moulding pliers

Preformed mesh is an anatomic, ready-to-use solution for the reconstruction of cranial defects. Off-the-shelf, ready-to-use sterile implants; anatomic shapes based on scientific study and clinic data; contoured to reduce bending & procedure time; economic solution with aesthetic results. Preformed Mesh is intended for use in fixation of the cranial bones in procedures such as reconstruction, fracture repair, craniotomies and osteotomies.

Timing of operation: 3 months after the skull defect, the pressure at the skull defect site is not high, and there are no factors that are not conducive to the healing of the incision, such as infection and ulcer.

Preoperative preparation: All patients had no contraindication to surgery, and all underwent cranial CT and frontal X-ray examination.In the digital molding group, thin-slice CT scan was routinely performed with a thickness of 2mm, and three-dimensional reconstruction of the frontal bone was performed. Then, the two-dimensional titanium mesh was molded by “titanium mesh digital molding machine”, and the two-dimensional personalized titanium mesh repair was completely consistent with the patient’s frontal bone defect, which was sterilized for later use.In the 3D easy plastic molding group, a 3D easy plastic titanium mesh more than 2cm larger than the defect edge was selected, which was premolded with a traditional mold and sterilized for later use.All patients underwent general anesthesia with endotracheal intubation and overlay repair.According to the size and shape of the frontal bone defect of the patients, the three-dimensional easy-to-plastic group cut the titanium mesh, manually molded the mesh as far as possible to meet the requirements of the patient’s defect site, polished the edge and put it at the bone window, and fixed it with a matching self-tapping titanium nail.Routine use of antibiotics to prevent infection, 1 ~ 2 days to remove the drainage tube, 10 ~ 12 days to remove stitches.The wound healing, plastic effect and complications of the patients were observed for a short period of time after surgery. The efficacy was finally evaluated according to the following criteria in the follow-up 3 months later. Excellent: reliable fixation of titanium alloy mesh plate, beautiful appearance, no postoperative complications; Good: Titanium alloy mesh plate fixed reliably, postoperative complications improved after symptomatic treatment; Rejected: titanium mesh slippage and displacement, or removal of titanium mesh due to other surgical complications.

Data copy 3D CT as far as possible to use 1-2 mm scanning, high precision data to make the statue more accurate.To copy data, it is necessary to copy the original DICOM data in the CT room to save data processing time.Try not to copy the image data in the workstation, which will make the process more complicated and less accurate.Causes time delay or molds can not be used.

Children skull repair matters needing attention: 1. Try to listen to the doctor’s advice by two statues because children’s skull is in the stage of development skull gyrus growing changes.Because the titanium mesh is a metal that will not grow, it will cause the asymmetry of the skull, which will affect the appearance and the development of the brain.2. Try to use three-dimensional titanium mesh, because three-dimensional titanium mesh is softer and has a certain expansibility. However, we should pay attention to let children not do too strenuous exercise as far as possible.

Product detail pictures:

Related Product Guide:

Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for Hot Selling for Eye Socket Plate - anatomical titanium mesh-3D cloud shape – Shuangyang, The product will supply to all over the world, such as: Nepal, Philippines, Finland, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

-

Factory making Trauma Locking Bone Screw - Can...

-

Cheap PriceList for Screw - InterTAN Intramedu...

-

China Cheap price Orthopedic Thorax Plate - Ti...

-

Professional China Thorax Locking Plate - Tita...

-

Factory Cheap Orthopedic Bone Plate And Screw F...

-

China New Product Locking Bone Screw - Distal ...