Ihe:ọgwụ titanium alloy

Nkọwapụta ngwaahịa

| Ihe Mba. | Nkọwapụta | |

| 11.07.0115.004124 | 1.5 * 4mm | Na-abụghị anodized |

| 11.07.0115.005124 | 1.5 * 5mm | |

| 11.07.0115.006124 | 1.5 * 6mm | |

| Ihe Mba. | Nkọwapụta | |

| 11.07.0115.004114 | 1.5 * 4mm | Anodized |

| 11.07.0115.005114 | 1.5 * 5mm | |

| 11.07.0115.006114 | 1.5 * 6mm | |

Atụmatụ:

•Alloy titanium ebubata iji nweta ike siri ike na mgbanwe kachasị mma

•Switzerland TONRNOS CNC akpaka ịkpụ lathe

•usoro ọxịdashọn pụrụ iche, melite ike nke elu nke ịghasa ma na-eyi nguzogide

Ngwa dakọtara:

cross isi ịghasa ọkwọ ụgbọ ala: SW0.5*2.8*75mm

aka kwụ ọtọ ngwa ngwa njikọ

Mpempe profaịlụ dị ala dị ala nwere akụkụ na profaịlụ efere sara mbara na-enye ihe ọ bụla enweghị ike ime. Dị n'ogologo ahaziri nke ukwuu.

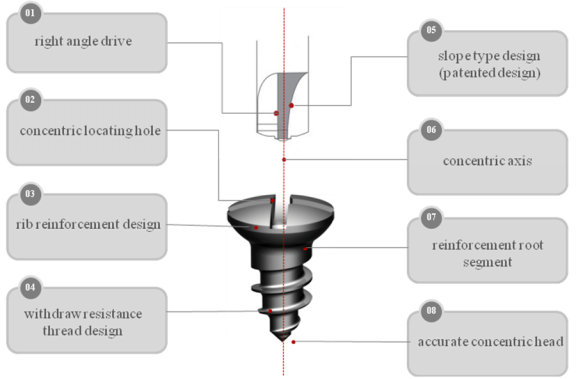

Uru nke skru titanium alloy:

1. Ike dị elu. Njupụta nke titanium bụ 4.51g/cm³, dị elu karịa nke aluminom ma dị ala karịa nke ígwè, ọla kọpa na nickel, mana ike dị elu karịa nke ọla ndị ọzọ. Ịghasa nke titanium alloy mere bụ ìhè na ike.

2. Ezigbo nguzogide corrosion, titanium na titanium alloy n'ọtụtụ mgbasa ozi kwụsiri ike, a na-etinye kposara alloy titanium n'ọtụtụ ebe na-emebi emebi ngwa ngwa.

3. Ezigbo okpomọkụ na-eguzogide na obere okpomọkụ.

4. Ndị na-abụghị magnetik, ndị na-adịghị egbu egbu.Titanium bụ ígwè na-abụghị nke magnet na a gaghị eme ka ọ bụrụ magnetized na nnukwu oghere magnetik. Ọ bụghị naanị na-adịghị egbu egbu, ma nwee ezigbo ndakọrịta na ahụ mmadụ.

5. Strong mgbochi damping arụmọrụ.Tụnyere ígwè na ọla kọpa, titanium nwere ogologo oge vibration attenuation oge mgbe n'ibu vibration na electric vibration.This arụmọrụ ike ga-eji dị ka n'iji ya gee ntị ndụdụ, vibration components nke ọgwụ ultrasonic grinders na vibration nkiri nke elu audio ụda.

Nhazi eriri maka mmalite ịghasa ngwa ngwa yana ike ntinye dị ala. Nhọrọ sara mbara nke efere na ntupu, gụnyere mastoid na meshes nwa oge, na oghere burr maka shunts.

The tighter na ịghasa, mma?

A na-ejikarị screws eme ihe na ịwa ahụ ọkpụkpụ iji mpikota onu ebe mgbawa ahụ, dozie efere ahụ na ọkpụkpụ, ma dozie ọkpụkpụ n'ime ime ma ọ bụ n'èzí nhazi nhazi. Nrụgide a na-etinye iji pịnye ihe nkedo n'ime ọkpụkpụ dị nhata na torque nke dọkịta na-awa ahụ na-etinye.

Otú ọ dị, ka ike na-agba ọsọ na-abawanye, ihe nkedo ahụ na-enweta ike kachasị ike (Tmax), bụ ebe a na-ebelata ike nke screw na ọkpụkpụ ma dọpụta ya n'ebe dị anya. Pull-out force (POS) bụ ihe mgbagwoju anya iji gbanwee ihe nkedo ahụ n'ọkpụkpụ. A na-ejikarị ya eme ihe dị ka parameter iji tụọ ike njide nke screw. Ka ọ dị ugbu a, mmekọrịta dị n'etiti oke ike na ike ndọpụ ka amabeghị.

N'ụlọ ọgwụ, ndị dọkịta na-awa orthopedic na-ejikarị ihe dịka 86% Tmax tinye ihe nkedo ahụ. Otú ọ dị, Cleek et al. chọpụtara na ntinye nke 70% Tmax na tibia nke atụrụ nwere ike nweta POS kachasị elu, na-egosi na enwere ike iji ike torsion dị ukwuu mee ihe na ụlọ ọgwụ, nke ga-ebelata nkwụsi ike nke nhazi.

Nnyocha e mere n'oge na-adịbeghị anya banyere humerus na cadavers mmadụ site na Tankard et al. chọpụtara na enwetara POS kacha elu na 50% Tmax. Isi ihe kpatara ọdịiche dị na nsonaazụ ndị a dị n'elu nwere ike ịbụ enweghị nkwekọrịta nke ihe atụ ndị a na-eji na ụkpụrụ nha dị iche iche.

Ya mere, Kyle M. Rose et al. site na United States tụrụ mmekọrịta dị n'etiti Tmax dị iche iche na POS site na kposara etinyere n'ime tibia nke cadavers nke mmadụ, ma nyochaakwa mmekọrịta dị n'etiti Tmax na BMD na ọkpụkpụ cortical. E bipụtara akwụkwọ ahụ n'oge na-adịbeghị anya na Usoro na Orthopaedics. Nsonaazụ na-egosi na enwere ike nweta POS kachasị na nke yiri ya na 70% na 90% Tmax na 90% Tmax na POSTmax screw torque dị ukwuu karịa nke 100% Tmax. Enweghị ọdịiche dị na BMD na cortical cortical dị n'etiti ìgwè tibia, ọ dịghịkwa njikọ dị n'etiti Tmax na nke abụọ dị n'elu. Ya mere, na omume ụlọ ọgwụ, dọkịta na-awa ahụ ekwesịghị ime ka ịghasa ahụ na-eji ike kachasị elu, ma na-eji ike dị ntakịrị karịa Tmax. Ọ bụ ezie na 70% na 90% Tmax nwere ike nweta POS yiri nke ahụ, a ka nwere ụfọdụ uru na-emebiga ihe ókè nke ịghasa, ma torque agaghị agafe 90%, ma ọ bụghị ya ga-emetụta mmetụta nhazi.

Isi mmalite: Mmekọrịta dị n'etiti Insertional Torque na Pullout Strength of Surgical Screws. Usoro na Orthopedic: June 2016 - Mpịakọta 31 - Okwu 2 - p 137-139.

-

Mkpọchi maxillofacial Obere ogologo akwa akwa

-

mkpọchi maxillofacial micro okpukpu abụọ Y efere

-

cranial snowflake efere interlink Ⅱ

-

Mkpọchi maxillofacial Obere efere kwụ ọtọ

-

φ2.0mm ịghasa nke onwe

-

Mkpọchi maxillofacial Obere rectangular efere