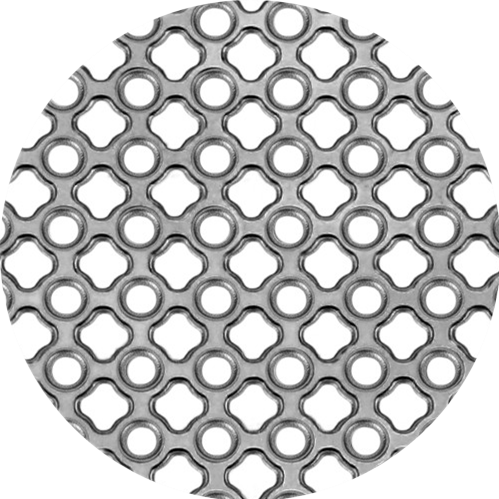

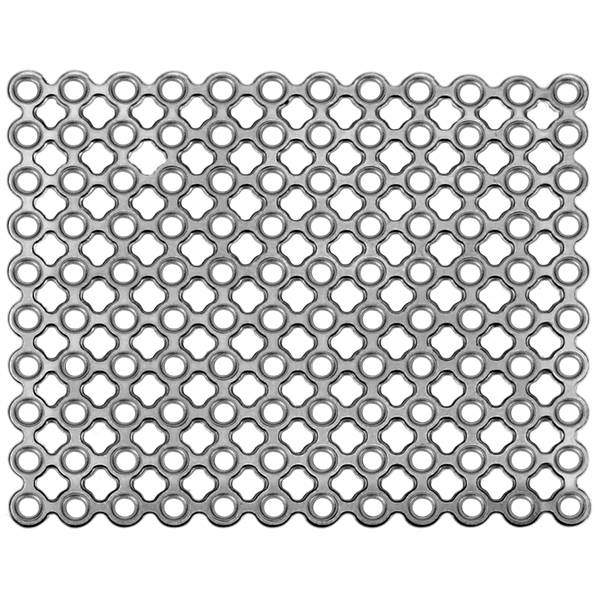

OEM/ODM Supplier Maxillofacial Hook Plate - flat titanium mesh-2D round hole – Shuangyang Detail:

Material: medical pure titanium

Product specification

|

Item No. |

Specification |

|

12.09.0110.060080 |

60x80mm |

|

12.09.0110.090090 |

90x90mm |

|

12.09.0110.100100 |

100x100mm |

|

12.09.0110.100120 |

100x120mm |

|

12.09.0110.120120 |

120x120mm |

|

12.09.0110.120150 |

120x150mm |

|

12.09.0110.150150 |

150x150mm |

|

12.09.0110.200180 |

200x180mm |

|

12.09.0110.200200 |

200x200mm |

|

12.09.0110.250200 |

250x200mm |

Features & Benefits:

Arcuate list structure

• Contact each holes, avoid the shortcomings of traditional titanium

mesh, such as distortion and hard to model. Guarantee the titanium

mesh easier to bend and model to fit the irregular shape of skull.

• Unique rib reinforcement design, improve the plasticity and hardness

of titanium mesh.

• No iron atom, no magnetization in magnetic field. No effect to ×-ray,CT and MRI after operation.

• Stable chemical properties, excellent biocompatibility and corrosion resistance.

• Light and high hardness. Sustained protect brain issue.

• Fibroblast can grow into the mesh holes after operation, to make the titanium mesh and tissue integrated. Ideal intracranial repair material!

• Raw material is pure titanium, smelted three times, medical customized. Performance of ttanium mesh is unfom and stable, have the best combination of hardness and flexbilty. 5 inspection procedures for quality guarantee. The finalinspection standard:no breaks after 180° double back 10 time

• Precise low-profile counter bore design make screws fit the titanium mesh closely, and achieve low-profile repair effect.

• Domestic exclusive optical etching technology: optical etching tech is not machining, will not affect the performance. Precise design and high precision processing wil ensure the holes of each titanium mesh have same size and distance, holes edge is very smooth.Athese help the overall performance of titanium mesh is uniform. When impacted by external force, wll nly meet overal deformation but not ocal fracture. Reduce the risk of re-fracture of the skll.

Matching screw:

φ1.5mm self-drilling screw

φ2.0mm self-drilling screw

Matching instrument:

cross head screw driver: SW0.5*2.8*75mm

straight quick coupling handle

cable cutter (mesh scissors)

mesh moulding pliers

It is available in a variety of shapes and sizes. Low profile for minimal palpability, Offered with smooth or textured bottom disks, Specially designed smooth disk edges.

The bones of the skull are in three layers: the hard compact layer of the external table (lamina externa), the diploë (a spongy layer of red bone marrow in the middle, and the compact layer of the inner table (Lamina interna).

Skull thickness vary from one location to another, so the impact site decide the traumatic impact which cause a fracture. The skull is thick at the external angular process of the frontal bone, the external occipital protuberance, the glabella, and the mastoid processes, Areas of the skull that are covered with muscle have no underlying diploe formation between the internal and external lamina, which results in thin bone more susceptible to fractures.

Skull fractures occur more easily at the thin squamous temporal and parietal bones, the sphenoid sinus, the foramen magnum (the opening at the base of the skull that the spinal cord passes through), the petrous temporal ridge, and the inner portions of the sphenoid wings at the base of the skull. The middle cranial fossa, a depression at the base of the cranial cavity forms the thinnest part of the skull and is thus the weakest part. This area of the cranial floor is weakened further by the presence of multiple foramina; as a result this section is at higher risk for basilar skull fractures to occur. Other areas more susceptible to fractures are the cribriform plate, the roof of orbits in the anterior cranial fossa, and the areas between the mastoid and dural sinuses in the posterior cranial fossa.

Cranial repair is a common operation in brain surgery to solve the problems of abnormal cerebral blood supply, insufficient or disorder of cerebrospinal fluid circulation and brain compression caused by skull defect.Craniocerebral trauma and brain surgery removal of bone flap, skull benign tumor or tumor resection, skull chronic osteomyelitis, etc.Because the skull defect area shape changes, the scalp is affected by atmospheric pressure, so that it invagination oppresses the brain tissue.Repair the defect area, make up for the mechanical safety protection problem of the brain tissue, solve the abnormal problems such as insufficient or disorder of cerebral blood supply and cerebrospinal fluid circulation, and also need to consider the repair and shaping problem of the original shape.Alleviate skull defect syndrome.Cranial repair should be performed for skull defects with a diameter of more than 3 cm, no muscle coverage, and no contraindications.It is generally considered that 3~ 6 months repair after craniotomy is appropriate.Children can be 3~5 years old after plastic surgery.

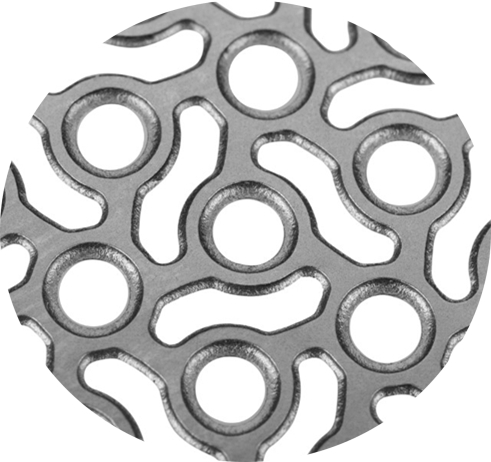

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for OEM/ODM Supplier Maxillofacial Hook Plate - flat titanium mesh-2D round hole – Shuangyang, The product will supply to all over the world, such as: venezuela, Adelaide, Eindhoven, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our solutions are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

-

Trending Products Mini Titanium Screw - 5.0 Se...

-

Rapid Delivery for Bone Screw Fracture - Cannu...

-

Good User Reputation for Titanium Nail - Calca...

-

High reputation Maxillofacial Rectangular Plate...

-

Professional China Large Fragment Instrument Se...

-

Trending Products Mini Titanium Screw - Distal...