Ibikoresho:ubuvuzi titanium

Ibisobanuro ku bicuruzwa

| Ingingo No. | Ibisobanuro | |

| 11.07.0115.004124 | 1.5 * 4mm | Ntibisanzwe |

| 11.07.0115.005124 | 1.5 * 5mm | |

| 11.07.0115.006124 | 1.5 * 6mm | |

| Ingingo No. | Ibisobanuro | |

| 11.07.0115.004114 | 1.5 * 4mm | Anodised |

| 11.07.0115.005114 | 1.5 * 5mm | |

| 11.07.0115.006114 | 1.5 * 6mm | |

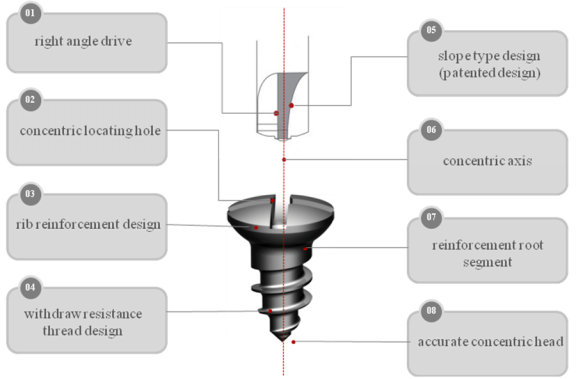

Ibiranga:

•yatumijwe mu mahanga titanium kugirango igere ku gukomera kwiza no guhinduka neza

•Ubusuwisi TONRNOS CNC ikata umusarani

•uburyo budasanzwe bwa okiside, kunoza ubukana bwa screw no kwambara birwanya

Igikoresho cyo guhuza:

umushoferi wambukiranya umutwe: SW0.5 * 2.8 * 75mm

Igikoresho cyihuse

Ultra ntoya yerekana isahani yerekana impande zose hamwe na plaque yagutse itanga muburyo budashoboka. Biraboneka muburebure bwihariye.

Ibyiza bya titanium alloy screw :

1. Imbaraga nyinshi. Ubucucike bwa titanium ni 4.51g / cm³, burenze ubwa aluminiyumu kandi munsi y'ibyuma, umuringa na nikel, ariko imbaraga ziri hejuru cyane kuruta iz'ibindi byuma. Imiyoboro ikozwe muri titanium yoroheje kandi ikomeye.

2. Kurwanya ruswa neza, titanium na titanium alloy mubitangazamakuru byinshi birahagaze neza, imigozi ya titanium irashobora gukoreshwa muburyo butandukanye bworoshye kwangirika.

3. Kurwanya ubushyuhe bwiza no kurwanya ubushyuhe buke.Imigozi ya Titanium alloy irashobora gukora ku bushyuhe bugera kuri 600 ° C na minus 250 ° C, kandi irashobora gukomeza imiterere yayo idahindutse.

4. Ntabwo ari magnetique, idafite uburozi.Titanium nicyuma kitari magnetique kandi ntikizakoreshwa mumashanyarazi murwego rwo hejuru cyane.Ntabwo ari uburozi gusa, kandi bufite aho buhurira numubiri wumuntu.

5. Imikorere ikomeye yo kurwanya damping. Ugereranije nicyuma n'umuringa, titanium ifite igihe kinini cyo kunyeganyega nyuma yo kunyeganyega kwa mashini hamwe no kunyeganyega kw'amashanyarazi.Iyi mikorere irashobora gukoreshwa nko guhuza ibyuma, ibice byinyeganyeza byubuvuzi bwa ultrasonic grinders hamwe na firime yinyeganyeza zijwi ryamajwi.

Igishushanyo cyinsanganyamatsiko yihuta yo gutangira no kwinjiza hasi. Guhitamo amasahani hamwe na mesh, harimo mastoid na meshes by'agateganyo, hamwe na burr umwobo wa shunts.

Gukomera cyane, ni byiza?

Imigozi isanzwe ikoreshwa mugubaga amagufwa kugirango igabanye aho yavunitse, ikosore isahani kumagufwa, kandi ikosore igufwa kumurongo wimbere cyangwa hanze.

Ariko, uko imbaraga za torque ziyongera, screw ibona imbaraga ntarengwa (Tmax), icyo gihe imbaraga zo gufata umugozi kumagufa ziragabanuka kandi zikururwa intera nto. Imbaraga zisohoka (POS) nuburemere bwo kugoreka umugozi mu magufa. Bikunze gukoreshwa nkibipimo byo gupima imbaraga zifata screw. Kugeza ubu, isano iri hagati yumuriro ntarengwa nimbaraga zo gukuramo ntikiramenyekana.

Mubuvuzi, abaganga babaga amagufwa mubisanzwe binjiza screw hamwe na 86% Tmax.Nyamara, Cleek nibindi. yasanze 70% ya Tmax screw yinjiza kuri tibia yintama ishobora kugera kuri POS ntarengwa, byerekana ko imbaraga za torsion zikabije zishobora gukoreshwa mubuvuzi, bikagabanya ituze ryikosorwa.

Ubushakashatsi buherutse gukorwa kuri humerus muri cadavers yabantu na Tankard nabandi. wasanze POS ntarengwa yabonetse kuri 50% Tmax.Impamvu nyamukuru zo gutandukanya ibisubizo byavuzwe haruguru zishobora kuba ukudahuza ingero zikoreshwa hamwe nuburinganire butandukanye bwo gupima.

Kubwibyo, Kyle M. Rose n'abandi. ukomoka muri Amerika wapimye isano iri hagati ya Tmax na POS zitandukanye ukoresheje imigeri yinjijwe muri tibia ya cadaveri yabantu, ikanasesengura isano iri hagati ya Tmax na BMD hamwe nubunini bwamagufwa ya cortical. Uru rupapuro ruherutse gusohoka muri Technique muri orthopaedics.Ibisubizo byerekana ko POS ntarengwa kandi isa na Tmax nini ya 90% na Tmax ya screw torque ya 90. 100% Tmax. Nta tandukaniro ryabaye muri BMD n'ubugari bwa cortical hagati yitsinda rya tibia, kandi nta sano ryari riri hagati ya Tmax na bibiri byavuzwe haruguru.Nuko rero, mubikorwa byubuvuzi, umuganga ubaga ntagomba gukomera umugozi hamwe nimbaraga nini za torsion, ariko hamwe numuriro uri munsi ya Tmax. Nubwo 70% na 90% Tmax ishobora kugera kuri POS isa, haracyari ibyiza bimwe byo kurenga umugozi, ariko itara ntirishobora kurenga 90%, bitabaye ibyo ingaruka zo gukosora zizagira ingaruka.

Inkomoko: Isano iri hagati yumuriro wumuriro nimbaraga zo gukurura imigozi yo kubaga.Ikoranabuhanga muri ortopedie: Kamena 2016 - Umubumbe wa 31 - Igitabo cya 2 - p 137–139.

-

gufunga maxillofacial mini igororotse ikiraro

-

gufunga maxillofacial micro kabiri Y isahani

-

cranial snowflake ihuza isahani Ⅱ

-

gufunga maxillofacial mini isahani igororotse

-

φ2.0mm yo kwikorera wenyine

-

gufunga maxillofacial mini urukiramende